Specialist Strategies for Preventing Weld Undercut Effectively

Understanding the Causes and Solutions for Undercut Welding in Steel Manufacture Processes

In the realm of metal fabrication procedures, the incident of undercut welding positions a considerable challenge that demands a detailed understanding of its reasons and practical services. The complex interplay of numerous aspects throughout welding operations can cause this unfavorable sensation, affecting the architectural stability and total top quality of the welded joints - Preventing weld undercut. By dissecting the origin creates of undercut welding and exploring efficient remedial measures, producers can elevate the criterion of their handiwork and guarantee the production of remarkable steel parts

Common Sources Of Undercut Welding

Frequently neglected in metal fabrication, undercut welding takes place due to various elements that demand precise interest and expertise to be efficiently reduced. In addition, improper welding methods, such as utilizing the incorrect welding angle or take a trip rate, can additionally add to damage development. The selection of welding criteria, such as voltage, current, and wire feed speed, plays a considerable function in the event of undercut welding.

Effect of Incorrect Welding Parameters

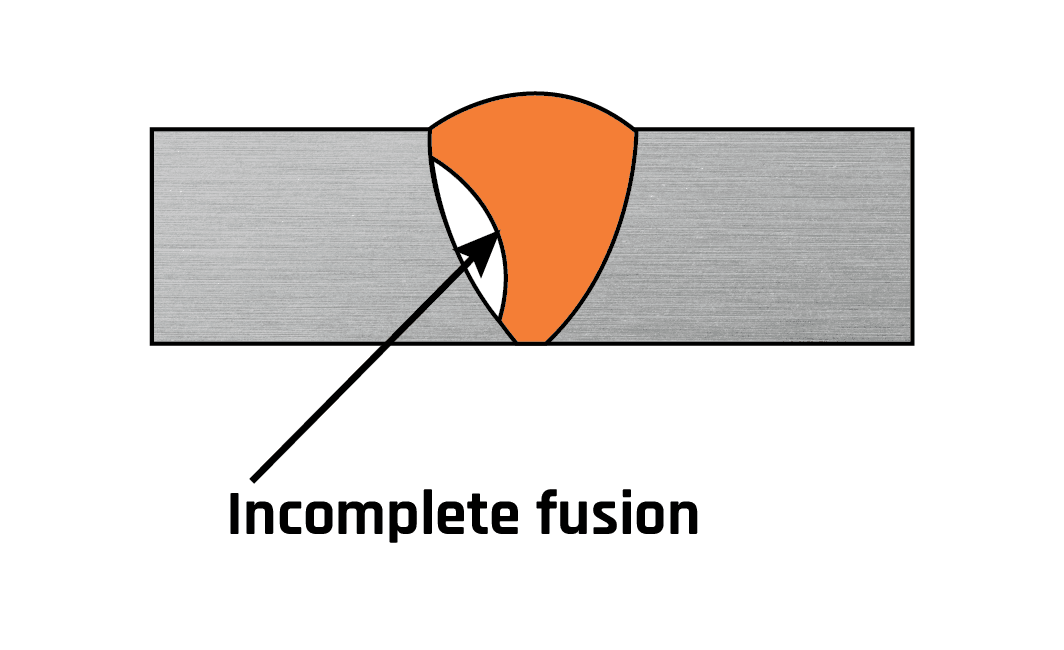

Inaccurate welding parameters can considerably jeopardize the stability and high quality of welded joints in metal manufacture procedures. The effect of inaccurate welding parameters materializes in various ways, causing structural weak points and defects in the bonded parts. One essential facet influenced by incorrect welding specifications is the penetration deepness of the weld. Not enough warm input because of low welding currents or exceedingly high traveling speeds can result in poor blend between the base metals, bring about insufficient joint penetration and weakened bonds. Alternatively, too much warm input brought on by high welding currents or slow-moving traveling speeds can bring about burn-through and too much reinforcement, developing a fragile and unstable weld framework. Additionally, wrong specifications such as improper voltage setups or inaccurate electrode angles can add to unpredictable weld bead accounts, lack of blend, and enhanced opportunities of flaws like undercutting. Thorough attention to welding parameters is extremely important to ensure the manufacturing of high-grade welds with the desired mechanical homes and architectural stability.

Result of Improper Lantern Angle

Inappropriate torch angle in welding operations can considerably affect the high quality and stability of the last weld joints in steel construction procedures. The lantern angle plays a critical role in determining the heat input and distribution during welding. When the torch angle is incorrect, issues such as damaging can arise. Damaging is an usual welding issue where a groove creates along the weld toe, damaging the joint and endangering its architectural stability.

A torch angle that is too steep can bring about not enough infiltration, incomplete combination, and increased spatter. On the various other hand, a torch angle that is also shallow can cause excessive infiltration, burn-through, and distortion of the base material. Preventing weld undercut. Appropriate torch angle is necessary for making certain constant weld high quality, strength, and look

To stop undercutting and other issues triggered by improper see page lantern angles, welders need to be trained to keep the right torch angle throughout the welding procedure. Routine monitoring and change of torch angles throughout welding can assist achieve audio welds with minimal issues.

Function of Inadequate Welding Techniques

One more element of insufficient welding methods is incorrect weld preparation. Inadequate cleaning of the base steels, wrong joint layout, or not enough side prep work can all add to undercut welding. Poor protecting gas protection or using the wrong kind of gas can result in insufficient combination and the formation of undercut issues.

To resolve the function of inadequate welding techniques in steel construction processes, it is necessary to give thorough training for welders. Appropriate education on welding criteria, joint prep work, and shielding gas option can assist avoid undercut welding and make certain high-grade welds in metal fabrication tasks.

Efficient Solutions for Undercut Welding

Addressing undercut welding in steel fabrication calls for executing effective options to enhance weld top quality and structural honesty. One of the key services to combat undercut is to change welding parameters such as voltage, present, and travel speed to ensure appropriate warmth input and combination. By fine-tuning these setups, welders can avoid too much melting of the base metal and filler product, reducing the probability of undercut formation.

Furthermore, correct joint preparation is critical in avoiding undercut. Making certain clean base metal surface areas without pollutants and making use of the suitable bevel browse this site angle can aid promote much better weld infiltration and lower the risk of undercut - Preventing weld undercut. Utilizing ideal welding techniques, such as weaving or oscillating the torch, can likewise assist in distributing warm uniformly and filling the weld joint properly, decreasing the opportunity of undercut defects

Additionally, choosing the proper welding consumables, consisting of electrodes and filler metals, is crucial in alleviating undercut. Using materials with suitable chemical structures and mechanical buildings can contribute to accomplishing sound welds with very little undercut. Routine assessment and quality assurance actions must likewise be carried out to identify and deal with undercut problems immediately, making sure the general stability of produced metal parts.

Verdict

To conclude, understanding the reasons and options for undercut welding in metal manufacture processes is crucial for attaining high-quality welds. By attending to typical causes such as wrong welding specifications, incorrect lantern angle, and insufficient welding methods, welders can avoid damaging and make certain strong, durable welds. It is important to take note of these elements and execute reliable remedies to boost the total welding process and end product top quality.